|

| |

MGT-RPM Knuck Mod

April 27,

2012 -

READ THIS FIRST!

All the stuff below is old, out-dated info. I am leaving it here so

that folks can see what we did a few years back. This mod worked real well - but

THESE KITS ARE NOT FOR SALE ANY MORE!!!

However, if you want to upgrade to larger

8mm stub axles, then I will bore out YOUR

RPM knucks (to utilize 8x16x5

bearings) for free. Please note:

there is no way to utilize the larger pillow balls. The larger pillow balls

require custom

hand-made Delrin (plastic) retainers, and I do not have the machine set up any

more to make them.

-------------------------------------------------------------------

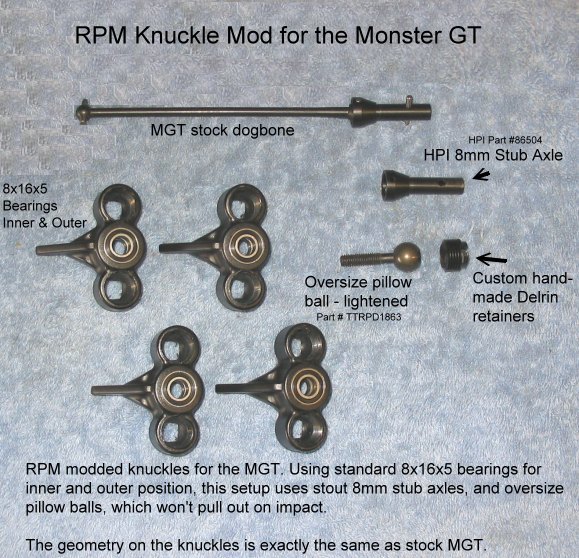

OK, myself and TheDude have been working on a knuckle solution. Some of our original work

started as a mod using TTR knuckles. Read about the

TTR knuckle mod here. Well, we had a few problems with knuckle breakage in the rear of

the MGT. The TTR plastic is just a little too brittle and breaks. In the front,

however, the TTR knuckles work great! So, we've been

arduously examining other alternatives and have come up with a solution using RPM knuckles.

The

modeled upgrade looks REAL GOOD. Here are some details and pics of the assembly and it's components...

Benefits of this system include:

| utilizes HPI 8mm buggy stub axles, which are virtually indestructible |

| uses standard (every LHS carries these) 8x16x5 wheel bearings (inner & outer), last much longer than small MGT bearings |

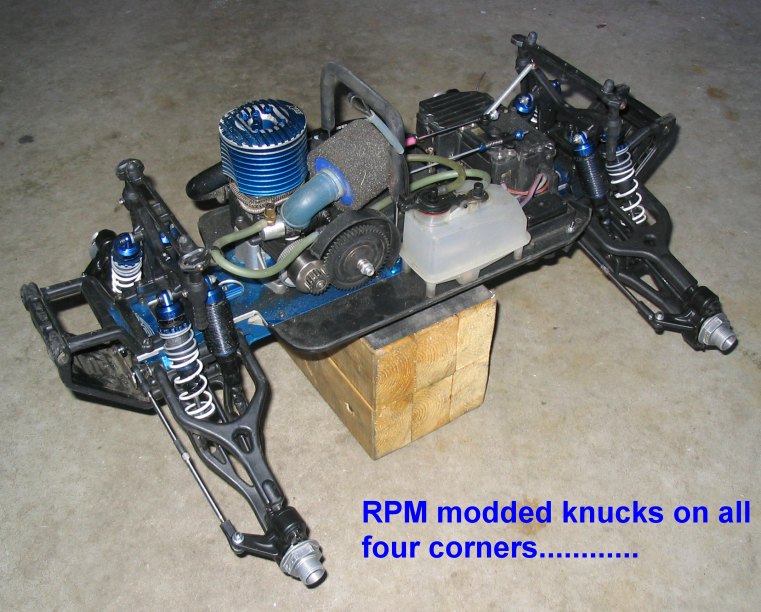

| RPM knucks can be used on all four corners |

| you can use stock a-arms, as well as RPM arms; your choice |

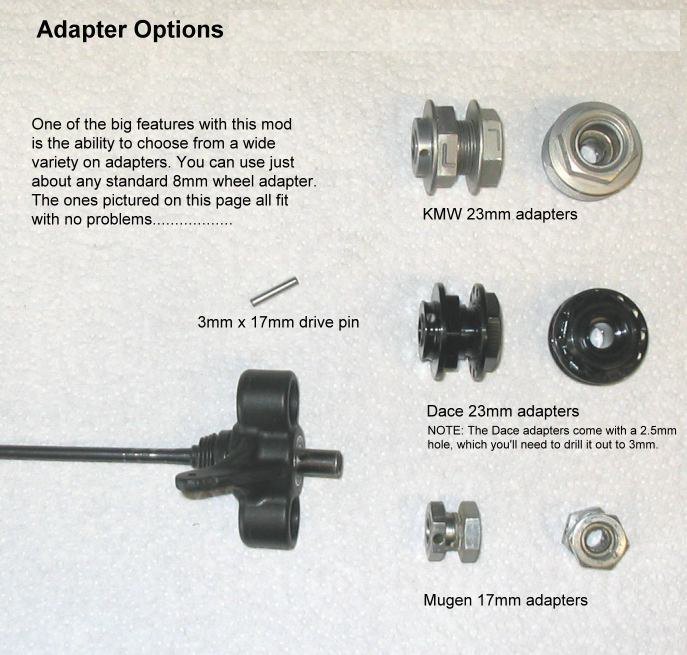

| use 17mm* or 23mm wheel hexes, as needed, very easy to swap |

| RPM knuckles are extremely tough, using flexible plastic** |

| RPM knuckles are exact same geometry as stock MGT knuckles |

| huge, lightweight pillow balls will not pull out on impact

(stock balls often do!) |

| large pillow balls allow you to Dremel knuckles out for steering mod

(your option) |

NOTE: this setup does NOT work with stock MGT 14mm hexes!

*NOTE #2: some 17mm adapters may slightly hit the Delrin retainers, so I advise

using 2mm offset 17mm adapters if you want 17mm adapters.

**NOTE #3: these modded knucks are NOT covered under RPM's lifetime warranty.

As of today (3/31/07), I (Chevy-SS) have decided NOT

to sell this kit. It's just way too labor-intensive to produce.

Here's what the MGT-RPM Knuck Mod kit will contain:

- Five modded knuckles (one for a spare,

just in case)

- Four HPI 8mm stub axles

- Four 3x17 pins to secure 17mm or 23mm

wheel adapter of your choice (wheel adapters NOT supplied)

- Four 5mm set screws (to hold the wheel adapter pins)

-

Eight 8x16x5 rubber

sealed bearings

- Ten (two for spares)

custom machined Delrin pillow ball retainers

- Eight lightweight

pillow balls

|

Installation of the MGT-RPM Knuck Mod:

The knucks

go on pretty easy, however, you need to do two things:

1) Drill out the a-arms for the larger pillow ball shafts, and,

2) Grind the front knuckles for extra steering.

The a-arm holes need to be drilled out to

accept the larger pillow ball shafts, however, the a-arms themselves remain at

the stock length. I used a 13/64" drill bit to enlarge the holes. Don't

go too deep. WHEN DRILLING - BE CAREFUL, AS THE DRILL WILL WANT TO PULL

ITSELF INTO THE HOLE, AND IF YOU GO TOO DEEP YOU RUIN THE A-ARM!!!!!!!!

The Delrin retainers can be

adjusted with a large screwdriver, or you can simply use a quarter or other

large coin. I recommend you re-check adjustment after running for a while. When

removing and re-installing the retainers, take your time to make sure the

threads align properly!

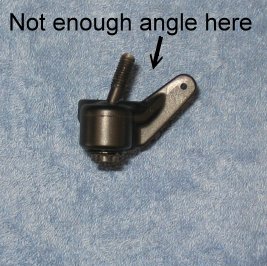

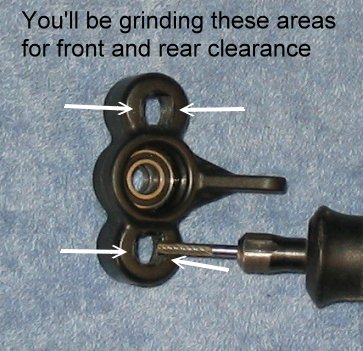

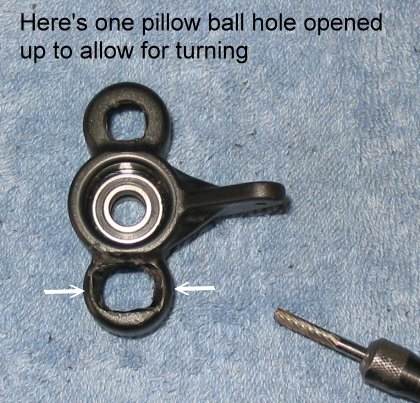

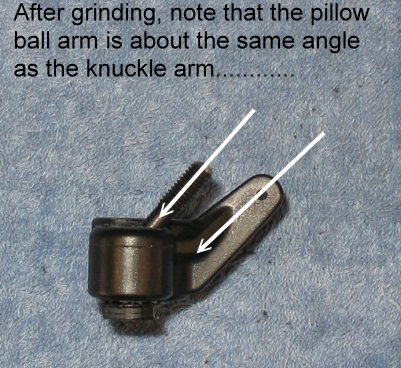

You will need to Dremel a little

bit of the front knuckles. Do it slowly and carefully. Get it so that the pillow ball shaft

lies at about the same angle as the knuckle arm.

The knucks will need some grinding for maximum steering -

|

|

|

|

|

Yeah, I know this doesn't look pretty, but it works just fine. I leave

the final grinding in your own capable hands.

|

|

|

That's it, you only need to do this to

the front knuckles. The rears should have enough for the up/down

movement, but it's always good to check and make sure. It's real easy to

clearance as necessary.

Just take your time and don't grind too much! I'm

sure you can do a prettier job than me, hahaha............. |

Now adjust toe and camber as usual. |

Pics of the

knuckle mod -

*NOTE #2: some 17mm adapters may slightly hit the Delrin retainers, so

(to avoid this) I advise using 2mm offset 17mm adapters if you want 17mm

adapters.

I don't think I've ever heard of anyone actually BREAKING a RPM knuckle. RPM

uses a proprietary plastic which is very strong and flexible. Unfortunately, the

flexing sometimes allows the small, stock pillow balls to pull out. But the huge

TTR balls won't pull out, that's for sure..........These modded knuckles are

awesome.

The front knucks needed quite a bit of Dremeling to get

"maximum" steering.

|

|

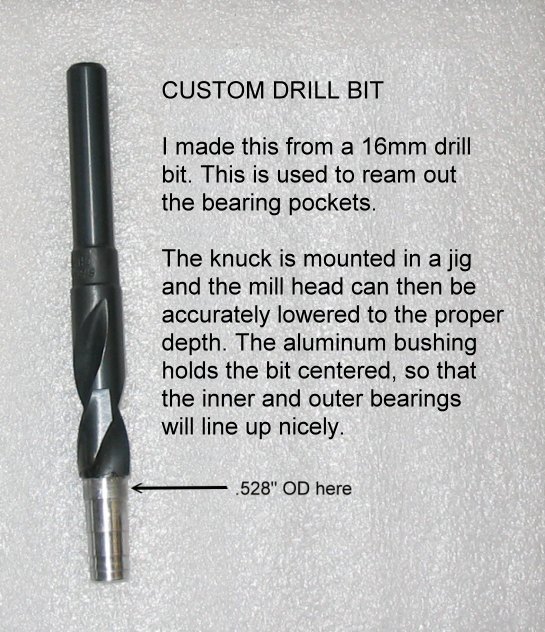

STEPS TO CREATE THE MOD - There's more to this mod than meets the eye. Here's a short summary of what

needed to be done:

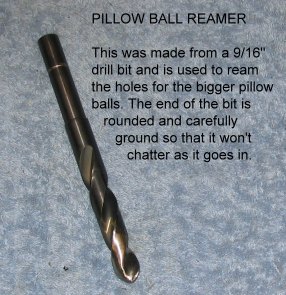

- Bore out stock pillow ball holes for oversize pillow balls, precisely

locating the new balls

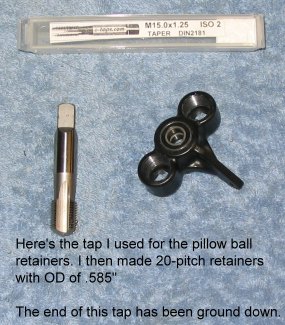

- Tap the new pillow ball holes

- De-burr and smooth the new pillow ball holes for smooth operation

- Bore out 15mm bearing pockets to 16mm, for inner and outer, precisely (and

I mean, it had to be PERFECT)

locating holes for depth and alignment

- Turn down (on lathe) 5/8" Delrin rod and hand-fabricate new pillow ball

retainers, one at a time, holding tolerances within .002"

- Test fit each and every piece by hand to ensure optimum fit

|

|

|

Note on JIGS

I made jigs to hold knuckles at various

stages. I made them out of plywood, as you're only milling plastic, so a

super-strong metal jig is not necessary. I used a jig for reaming and

tapping the pillow ball holes.

For drilling out the bearing pockets I

used a piece of 2"x4" wood and drilled a 3/4" hole in it, then held the

knuck (with my fingers) over the hole. The 3/4" hole was so the .528" guide

pin would have a spot to go into. |

Note on tap in pic above: it is NOT the stock 15mm thread. The stock

thread is 15.0x1.0

The machining process is slow and laborious. Everything needs to be pretty

damn accurate and it takes time to set up (and switch) the tooling and the jigs.

The Delrin retainers are all lathe-cut by hand and we can only make about a

dozen per hour, so this is not a high-quantity production line..................Another

option may be to take some stock 15mm aluminum retainers and use a Ball End Mill

to hollow them out a bit, then just thread the knuckle appropriately. I didn't

want the pillow ball contacting metal, so I used Delrin plastic.

-

|

![]()